"BIG FOOT 41"

or

2007_03 till 08

or

"What

happened whilst the last months!"

In summer 2006 I

had bought an ex German army 28V, 73 Ampere Diesel generator with noise

insulation and had the luck that it was one of the rare with starter motor! The

idea was to mount it at the trucks frame. A place was identified quickly,

the move of the starter batteries into the cabin

was done by purpose (pls. refer to here) plus

the move of the air tanks into the frame (please refer to here), only the

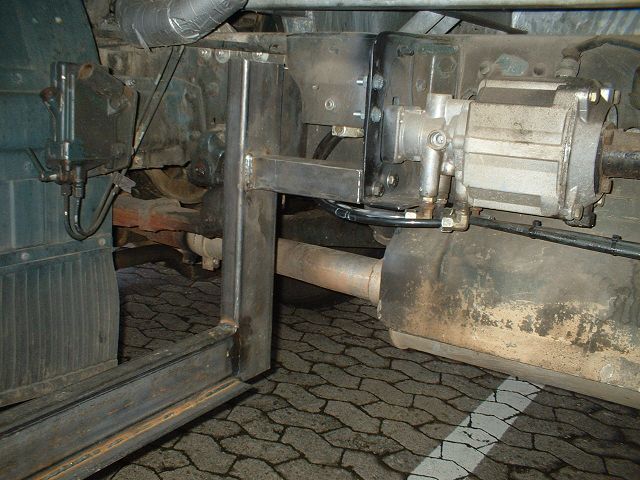

master brake cylinder remained. So I welded in March 2007 two supports to fit

the generator, her the one in front

:

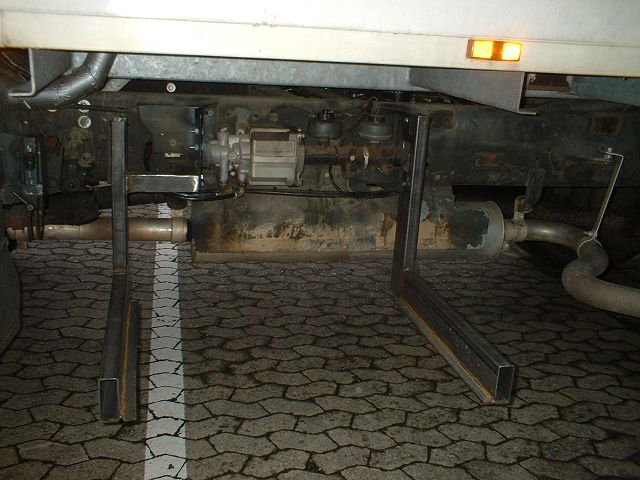

the rear:

and here

the overview:

But

exactly the master brake cylinder which you can see in the middle interfered too

much with the generator and as a result it reached out too much over the edge of

the cabin. So the idea was to modify the housing of the generator.

Here you

see the already taken off control unit. All the control panels and on- and

off-switch I wanted to have in the cabin , the emergency switch-off plus

connector should move the side, connector for remote control was for my purpose

no longer required. So once taken off I could fit a plain piece of metal and cut

off the rest of the housing till here.

But first

I had to extend the cables for the controls and switchers by using two different

trailer sockets, which will be connected with multi-wire cables and trailer

cable plugs. So the complete unit can be (dis-)connected quickly and easily

without mixing up, the connection for the Diesel to the main tank is anyhow by a

standard Army quick-release connector.

Here nearly

ready, only the second trailer connector is missing:

When

cutting off the housing walls I wondered a little bit that there weren’t that

many sparks but found out very quickly the reason when I wanted to weld the

walls into the new, L-shape form: Army lightweight! Aluminium!! I don’t want to

know what the beast would weight in normal metal, even with Aluminium housing it

was already 150 kg!! OK, welding iron is OK for me but Aluminium??? What would I

do without knowing Franz-Jakob and his

company! So his expert for Aluminium - Tobias – formed some new parts and

welded for me in a view hours in a perfect way the new shape of the housing.

Before putting the generator into the support I pre-sprayed and then sprayed in

colour RAL 1002. Here you can see the new L-shaped design and the modified

control unit:

As

mentioned before the cables were extended into the cabin to built everything

into the control panel. This shows the disaster BEFORE adding the additional

cables (it more than overdue that I spend some time to lay the cables perfect

and to add some connectors for quick disassembly – at least I think to have all

the required parts!:

The

supports were galvanized and – again – with the fantastic and gracious support

from Franz-Jakob and Tobias I built an additional cover for the generator. The

additional cover is required because even when driving on wet streets lots of

dirt and water got through the air inlet into the original housing. So if really

crossing a river or so it would be completely flooded! Here you can see in the

background already the rear part and at the end of the vertical support the a

welded in tube to extend the exhauster.

A view

from the rear including the housing which cover bottom and front in one piece.

This is

the new cover with all parts mounted, including the top cover fixed by rubber

type fasteners. The different parts are hopefully well enough water proved

mounted together by using foam rubber in between., same applies for the top

cover.

What

still misses: I need three waterproof shutters, ideal would be driven by motor:

1x for the exhaust, 1x for the air intake and 1x for blowing out the hot air. My

wish is to push a button before I start the generator which opens all three

shutters and simultaneously fans start to support the normal ventilation. Three

waste water shutters with ~ 9 cm (3”) should be sufficient and with ~. EUR 25,-

pricewise OK.BUT ONE motor to open / close the shutter costs as a standard part

~ EUR 170,-. This is definitely too much for that little bit of comfort,

especially because I need it for all three or nothing. So I have to look for

another solution, update hopefully soon! :-)

The rear

camera from the well-known manufacturer Waeco had more and more problems to

start. After the last tour it went completely into strike. So I made a bid in

Ebay for a “cheap” alternative: Colour instead of Black & White, including LED’s

and specified 1 LUX sensitivity, integrated microphone, waterproved housing up

to IP 67 and 160° wide angle lens.

I was afraid to lay new cables all the finished cabin but luckily the cabling

from the Waeco had sufficient additional wires (although quite thin). In

addition I was now more then lucky that I had laid the audio cable

when I installed the 7” monitor in the drivers

cabin (please refer to here on the bottom) - although I didn’t see the

reason in those days … but now I was lucky to have done it. Mounting the camera

in the rear was the easiest job, more tricky was the connection of the different

cables. So now I am enjoying a nice colour picture by daylight and even at night

I see at least without the rear lights a little bit in black & white (night

modus). I am curious how long this “low-cost” version will last compared to the

brand-label.

On a tour

last year in autumn the air heating had failed! Due to the good isolation of the

cabin it was still warm enough in the morning, but .... .

So redundancy was required and an identical, additional Eberspächer hot air

heating was integrated into the air ventilation system. With a shutter it is

possible to split the ventilation circuit so that both heaters are working

simultaneously but for different areas (I hope that my calculation for the air

flow due to the installation manual was correct).

In the

same go I installed the new, additional diesel pumps for the heating system for

elevations ABOVE 1.850 metre. Reason: The higher you get the thinner the air

will be and in comparison the normal pump will supply to much diesel which will

cause functionality problems with the heating units. The solution are special

pumps with a lower rate. Unfortunately the water heating has its diesel pump

integrated into the housing, so currently the fifth diesel pump is not built in.

So here I have to consult the local Bosch service for their advice or ask some

friends for their ideas to switch off the built in one and use only the

additional one.

To switch

all together in one go the pumps are operated by a relay. The sockets for the

relays are already fitted but the relays themselves not (on the picture). The

switch is integrated in the switch board, on the right you can see the two timers

for the air heaters.

And the

complete switch board including the items from the generator now looks as

follows:

Last but

not least a modification which will increase the rear ramp angle respectively

will minimize distorsion e. g. when driving though. The registration plate

underneath the reaer lamps

was moved to the middle of the

cabin. The previous bottom end under the rear lights was cut off..

Sorry that it

was so much more then usual but it was as well a long time since the last update

and I had hoped to finish some bits earlier and so to send different updates.

But finally everything was (more or less!!) finalised all together.

To be

continued!!!

Besucher/Visitors

Besucher/Visitors