"Big Foot 49"

or

Electric ...

The way how dramatically I miss-guessed

the required time for the work on electric was tremendous. Here just one

example for the new automatic cut-out:

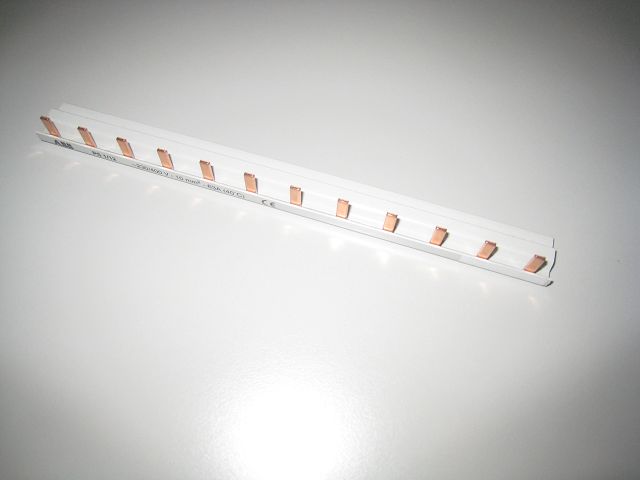

First of all I needed a copper-stripes to

power 6 of the automatic cut-outs simoultaniously -

as long as required like that . To do so I bought cupper connectors for

automatic cut-outs of house installations.

The plastic isolation was removed and the

hooks cut off.

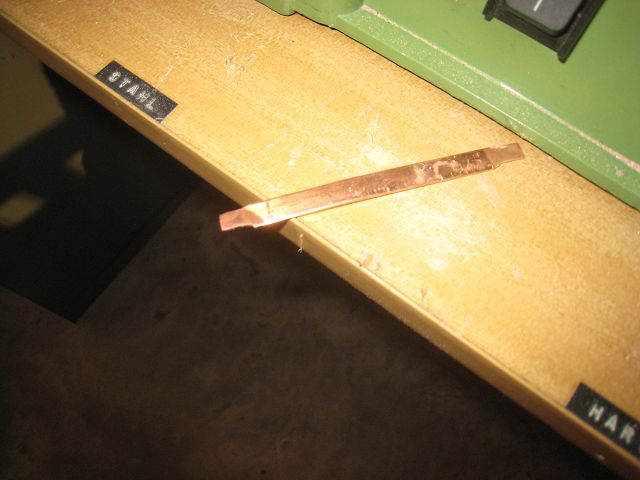

Afterwards the sharp edges were removed

and the pieces reduced to the required length. Due to the heat of the cutting,

polishing etc. the parts needed to be cooled down again in water.

Both edges were made smaller and thinner

plus a short use of the drilling machine (not done so far on this particular

strip) so that flat connectors (typically used in car industry, 6,3 mm) could be

pushed on and wan't fell off again.

Afterwards I drilled holes to connect the

stripes with the automatic cut-outs with screws - of course the drills were

deburred finally.

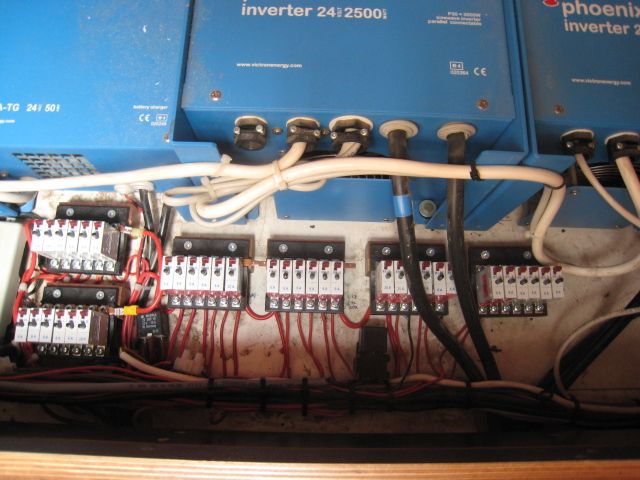

After the raisers had been made out of

hardwood ...

... and the automatic cut-outs had been

mounted on the plastic holders with screws, then together with the wooden

raisers had been screwed to the ground and finally all had been wired it finally

looked like that:

The normal fuses in the drivers cabine

were removed as well. Here I only needed a metal stripe to combine two plastic

holders together, the multi-cable-connectors fitted perfectly. And the depth to

the rear and top was as well more than sufficient - so against my original

worries even easierthan the exchange of the fuses in the cabine.

The automatic cut-outs I have bought from Thomas

Hirschberg, he still has more to sell ,

WHO IS

INTERESTED PLEASES CLICK HERE or here for his

private website.

A really nice guy gave me some of these

muliple sockets with a securing hook which prevents that the plug can fall off

accidently - thanks again very much Karl-Heinz (he knows whom I am talking about)!

(It is obsolete to mention that so far never a conventional plug

fall off, but now it is PERFECT!)

And because I had several of these

multiple sockets it was OK to "canibalize" one for single use, here e. g. to

connect the cooking plate. So I integrated one of these sockets into a small -

here without the cover.

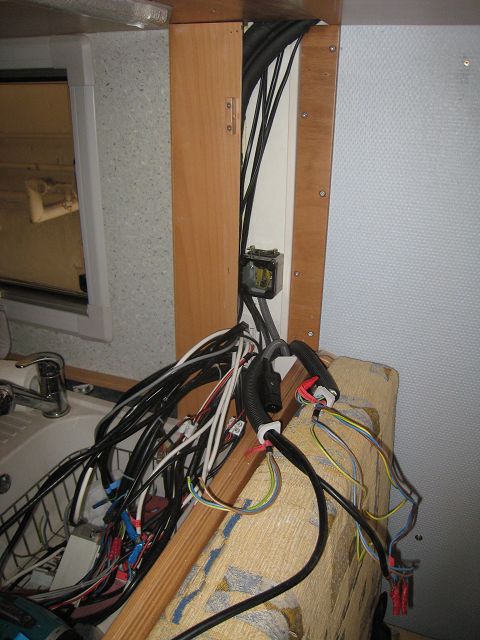

Yeah, ther rear part of the switch-board

was since a long time something which I didn't like.

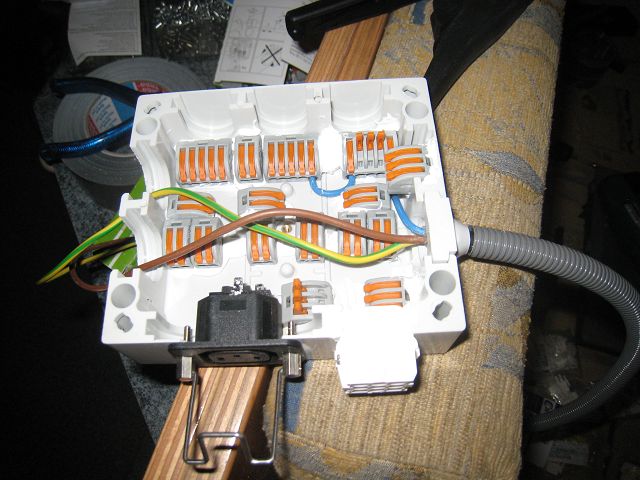

So first of all I separated the 230V-installation

completely from the 12V- and 24V-system. The patching is installed in a separate

box.

Thats how it looks when I had finisched

the wiring and applied protection tubes.

And here with cover!

The 12V & 24V-installation was

combined on several plugs and sockets for flat connectors 6,3 mm.

Because of the huge amount of wires I had

to use ~15 plugs and sockets which I didn't ike in case of service - too many to

dis- and re-connect, even if it is a service board which I will open only very

rarely and only in case of service or when I want to add anything!!

So finally I changed everything again and

have refitted everything on a special 9-pin socket for 230V, 1x 16-pin-socket, 1x 16-pin

plug, 1x 37-pin socket plus one remaining 6-pole socket for 6,3 mm flat

connectors (no other choice because of the 2,5mm² cables for switching on / off

the water pumps).

Thanks to Mark for organizing the

special-coloured and fine-wired cables!

The rear side of the switch board:

The Eberspächer airheating didn't work as

expected and so I had to apply an additional temperature sensor. Without these

sensors the fan is permantly on so that the sensor integrated in the air heating

can recognize more or less accurate the temperature of the room. The sensors

were integrated for boht air heatings.

Last but not least I have finished the

installation for the 24V generator:

| As soon as I engage a switch on switch

board a pneumatic valve opens by two pneumatic cylinders the covers to the

housing of the generator (pls. have a look as well

here). |

| Simultaniously the vans start to work (two

push cool air in, two pull out the hot air). |

| A magnetic valve opens the diesel

supply. |

This was the status so far.

The remaining problem was the exhaust. The exhaust of the generator is next to

the "in"-cover and the first idea to push out with a third van the exhausts

would have failed sooner or later because the dust and dirt of the exhausts

would have damaged the van quite quickly.

So I built an electric waste water valve in front of the exhaust. So I was able

to operate without an additional van because it is now a straight flow of the

exhausts.

The electric valve needs ~ 5 sec. power to run open and the same time but

reversed connection of "+" & "-" to close.

This would have required an additional switch in the control board (which would

have 1. ment to use an additional wire was and 2. I wouldn't have liked long

time because I prefer simple handling - even if this means that the workload to

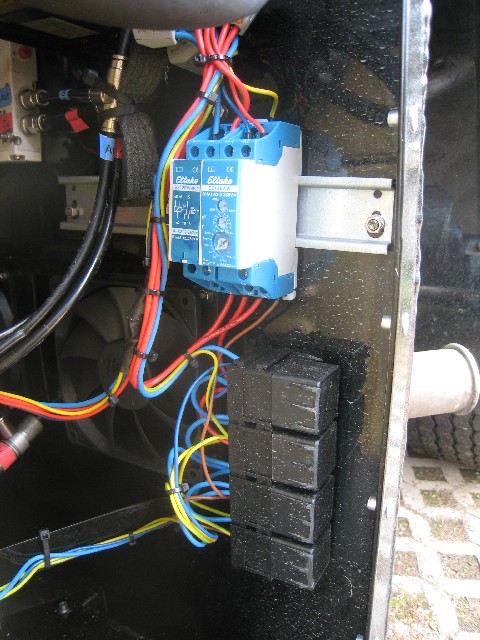

achieve that goes into extrems) and so I built in two special relays. The first

gives once I have switched the above to "on" for 5 sec. power (passing

make-contact). The second

switches for 5 sec. to "on" once the above switch is turned to "off"

(passing break-contact). Both 5

sec. power impulses go to 4 more relays to change the polarity (the first two to

give "+" and "-" to the valve to open, the next two to give "-" and "+" to the

valve to close).

Thanks as well to

Mr. Streubel from company Streubel

Automation resepctively Pneumatikwelt.de for his quick, friendly and

friendly support to me and this project. He is my supplier for the pneumatic

cylinders etc..

Definitely NO thanks to

Conrad respectively their bullsh...

forwarding agent Hermes, who delayed the shipment of elektric parts to 1 WEEK!!

Note: The last shipments arrived well in time due to Deutsche Post - much better

now!

The final test will be next Thursday when

I will join the ralley "Dresden-Breslau" - another update to follow.

Besucher/Visitors

Besucher/Visitors